You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pumps 101

- Thread starter Hotwaterwizard

- Start date

Hotwaterwizard

Hotsy Service Tech

Hotwaterwizard

Hotsy Service Tech

Hotwaterwizard

Hotsy Service Tech

In Real Life the solutions are much Different. If you want me to make one of my own Tell me you are interested by posting on my own board!

My web Page

My web Page

Hotwaterwizard

Hotsy Service Tech

Hotwaterwizard

Hotsy Service Tech

Hotwaterwizard

Hotsy Service Tech

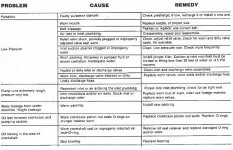

Pump Dammage Causes

What causes Pump Dammage ?

1) Cavitation. The pump will starve of water and the air in the system will make tiny explosions in the head and will dammage packings, valves and, plungers. Check your filters regularly if you have them.

2) The unloader is set too high. The unloader will spike if set too high. The pressure should be only about 400 psi higher on the spike. When the unloader is set too high it will cause the same dammage as Cavitation.

3) No inlet screen. If you don't have some kind of filter on the input side of the pump trash can get in the pump and do dammage. Sand is the most common thing to find inside of a broken pump.

4) Running the water from the bypass back into the inlet of the pump. The longer you run your machine with out pulling the trigger the hotter the water becomes. This is caused by friction. The Molecules moving in a constant circle builds up heat and will dammage your pump. If you have a tank available Run your bypass into the tank. Also as a general rule If you don't pull the trigger for 3 min or more Shut the machine down to save your pump.

What causes Pump Dammage ?

1) Cavitation. The pump will starve of water and the air in the system will make tiny explosions in the head and will dammage packings, valves and, plungers. Check your filters regularly if you have them.

2) The unloader is set too high. The unloader will spike if set too high. The pressure should be only about 400 psi higher on the spike. When the unloader is set too high it will cause the same dammage as Cavitation.

3) No inlet screen. If you don't have some kind of filter on the input side of the pump trash can get in the pump and do dammage. Sand is the most common thing to find inside of a broken pump.

4) Running the water from the bypass back into the inlet of the pump. The longer you run your machine with out pulling the trigger the hotter the water becomes. This is caused by friction. The Molecules moving in a constant circle builds up heat and will dammage your pump. If you have a tank available Run your bypass into the tank. Also as a general rule If you don't pull the trigger for 3 min or more Shut the machine down to save your pump.

Attachments

Last edited:

hey wiz, need more hits in this section to keep alive.

Hotwaterwizard

Hotsy Service Tech

I could just start adding a bunch of stuff to this forum to make it look like someone is interested in my stuff.

Deckcareplus

Deck Care Pro

Wiz,

Funny you should post this. I am considering rebuilding my first pump over the slow winter months. What do you recommend I get to do such a job. Is there a checklist of parts and tools I will need?

Funny you should post this. I am considering rebuilding my first pump over the slow winter months. What do you recommend I get to do such a job. Is there a checklist of parts and tools I will need?

Hotwaterwizard

Hotsy Service Tech

A 30mm socket to remove the valve caps

a 6mm Allen Wrench or a 13mm socket depending on the pump.

a packing removal tool.

a pair of needle nose pliers

an o-ring pick

a 17mm socket if the ceramic plungers are cracked

a vice maybe

That should do it.

a 6mm Allen Wrench or a 13mm socket depending on the pump.

a packing removal tool.

a pair of needle nose pliers

an o-ring pick

a 17mm socket if the ceramic plungers are cracked

a vice maybe

That should do it.

Hotwaterwizard

Hotsy Service Tech

I rebuild Pressure Washers for a living. I got the info out of my head.

Here is the General Pump Service Manual

http://generalpump.com/PDFs/TECHNICAL DATA/ServiceManual.pdf

Here is the General Pump Service Manual

http://generalpump.com/PDFs/TECHNICAL DATA/ServiceManual.pdf

GraffBuster

New member

Hey, Wiz, good stuff! {insert "thumbs-up" smilie here}