Please help me to understand.

If i use upstream injection and am mixing my supply water and chem before the pump and have a true 5 gpm pump. I should be getting 5 gpm from the tip.

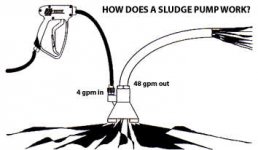

Now the same pump and downstream injection or x-jet type downstreamer. Is the pump pushing 5 gpm PLUS the draw amount?

So do you flow more with downstreaming then upstreaming?

If it takes 90 sec to empty a 5 gal bucket of chem useing my x-jet.

Am i really getting 8.5 gal per min out of the tip?

The x-jet will draw from 100 ft. if i hooked the supply line from the x-jet to the supply tank to rinse cement or trucks. Did i just increase the amount of GPM and be able to rinse faster?

Are chems less deluted if upstreamed compared to downstreaming?

upsteam is 80% water and 20% chem?[tip exits 5 gpm]

downstreaming is 100% water with 20% chem added?[tip exits 6.5 gpm]

X-jet 100% water and 75% chem?[tip exits 8.5 gpm]

I cant see where my thinking is messed up.

I was under the impression that the pump put's out the 5 gpm no matter what.

maybe i just need to get more sleep?

If i use upstream injection and am mixing my supply water and chem before the pump and have a true 5 gpm pump. I should be getting 5 gpm from the tip.

Now the same pump and downstream injection or x-jet type downstreamer. Is the pump pushing 5 gpm PLUS the draw amount?

So do you flow more with downstreaming then upstreaming?

If it takes 90 sec to empty a 5 gal bucket of chem useing my x-jet.

Am i really getting 8.5 gal per min out of the tip?

The x-jet will draw from 100 ft. if i hooked the supply line from the x-jet to the supply tank to rinse cement or trucks. Did i just increase the amount of GPM and be able to rinse faster?

Are chems less deluted if upstreamed compared to downstreaming?

upsteam is 80% water and 20% chem?[tip exits 5 gpm]

downstreaming is 100% water with 20% chem added?[tip exits 6.5 gpm]

X-jet 100% water and 75% chem?[tip exits 8.5 gpm]

I cant see where my thinking is messed up.

I was under the impression that the pump put's out the 5 gpm no matter what.

maybe i just need to get more sleep?

Last edited: