Dlee, send me your e-mail and i will send you the instruction book for the 15 A insulation. Or go to www3m.com/firestop and do a search for the instructions, listings, approvals and info about the access panels. 3M has their own access panels, but you can use other panels if installed as per 3M instructions.

A set of portable shears will work to cut the access panel holes, or tinsnips or a nibbler. I figure an hour to install a panel. Now it does not take that long to cut the hole, but figure set-up time and time to decide on the best location, and you do have an hour involved.

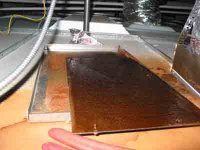

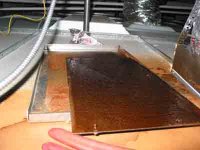

If you need some insulation, let me know. I have some on order for a job. I will say that the insulation is not cheap, about $7.80 a square foot, plus a roll of tape at $20.00. the insulation comes 1.5 inches thick x 24 inches x 20 feet or 1.5 inches thick x 48 inches x 20 feet. It is also available 2 inches thick.

These installs by unknowlagable or uncaring contractors are a real problem for all concerned. Maybe you can educate the inspector and he can educate the insulation installer.

Douglas Hicks, not certified to tape a bit of insulation to a duct. Maybe I can pay someone $6,000.00 bucks for a class. But only if a razor knife is included.

General Fire Equipment Co of Eastern Oregon, Inc